WSW Technology Knowledge: Influence of surface roughness on vibration value of deep groove ball bearing

The influence of surface roughness on the noise of deep groove ball bearings is studied and discussed

Abstract: in view of the high quality requirements, wide application and poor competitiveness with the international market of domestic low-noise deep groove ball bearings, the influence of surface roughness on the noise of deep groove ball bearings is studied and discussed. Combined with the actual situation in China, a more reasonable solution is proposed.

Key words: deep groove ball bearing; Channel; Roughness; Vibration value; Noise

At present, China's deep groove ball bearings have problems such as high vibration value and significant abnormal sound, which have seriously affected the product quality and international market competitiveness. This paper mainly studies the influence of surface roughness on vibration acceleration and velocity. This paper analyzes the mechanism of high vibration value from the perspective of surface roughness, and puts forward specific solutions through experimental verification and combined with the actual situation in China.

1 Test equipment and test results

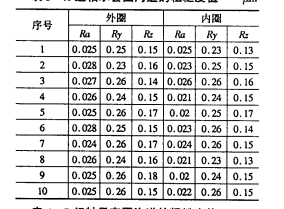

Take three groups of ten sets of Z3 (ZV3) grade 6201 bearings, group A and group B are foreign famous brands, and group C is a domestic high-quality brand. The inner ring and outer ring roughness parameters Ra, Ry and Rz were tested with a surface roughness meter (Taylor meter accuracy 0.01 fun) after the sleeve was removed without damage and cleaned. The vibration acceleration tester is 50910, and the vibration velocity tester is BVT. During the test, take 3 average points on each side of the bearing and the average value of 6 points as the final result.

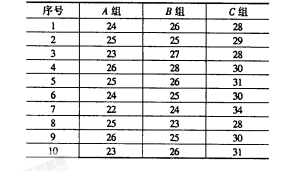

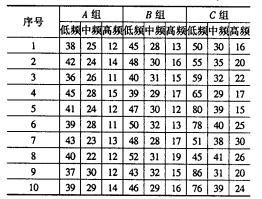

From the results of vibration values in Table 1 and table 2, the vibration values of group C bearings are generally higher than those of groups A and B, and the uniformity is poor. Because the factors that affect the vibration value of bearing include roundness and waviness, which mainly affect the low frequency, medium frequency and acceleration of speed; In this test, only microscopic factors are considered, so only high-frequency values of acceleration and velocity are referred.

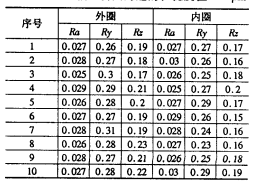

Table 1 vibration acceleration value

Use Taylor meter to measure the roughness parameters of inner and outer ring channels respectively. See Table 3, table 4 and table 5 for specific data.

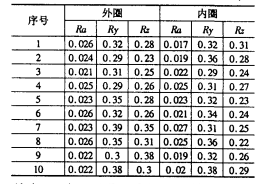

Table 2 vibration speed value

Table 3 roughness value of group a bearing ring groove

Table 4 roughness value of bearing ring groove of group B

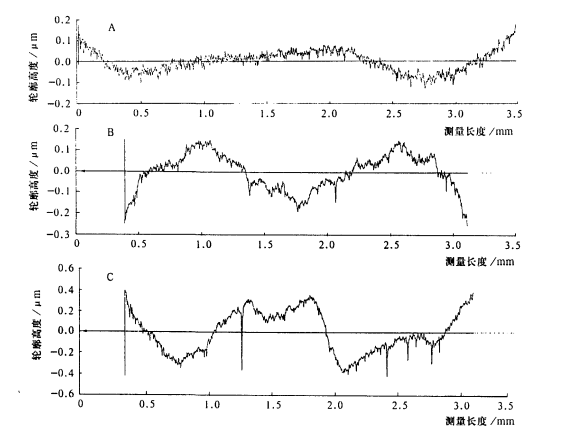

Fig. 1 measured diagram of channel surface morphology

Table 5 roughness value of group C bearing ring groove

It is obvious from table 3 to table 5 that although the Ra value of group C bearings is very good, the Ry and Rz values are significantly higher than those of groups A and B.

The bearing groove surface of group C is not as uniform as that of group A and B, and the ups and downs are abnormal. By selecting a 20x magnifying glass, it can be clearly seen that the silk path on the surface of bearing channels in groups A and B is a uniform parallel line, while the silk path on the surface of bearing channels in group C is not obvious and there is wire breakage. The measured results of the surface morphology of the bearing channel are shown in Figure 1.

2. Result analysis

Through the test, it can be considered that the important reason for the high vibration value of domestic low-noise bearings is the high Ry and several values on the channel surface and the poor uniformity. At present, most of the domestic detection of the ultra precision quality of the channel surface only pay attention to the Ra value, while ignoring the equally important foot and Rz value.

It is generally believed that the high ry and RZ values are caused by the following reasons:

(1) During channel grinding, the surface evenness has become poor.

(2) The abrasive particles of super essential oil stone are uneven, and the strength of bond is not enough, so the abrasive particles are easy to fall off.

(3) the ultra precision process parameters are improperly selected, and the cutting angle of the ultra precision process is too large.

(4) The ultra precision pendulum has vibration and poor stiffness.

According to the test analysis, it is suggested to take the following measures in combination with the specific situation:

(1) Strictly control the surface morphology of ferrule in groove grinding process.

(2) Strengthen the monitoring of ry and value of super precision process.

(3) According to the performance of different machine tools, select reasonable process parameters of superfinishing process.

(4) Strengthen the inspection of the quality of oilstone.

More about WSW Deep Groove Ball Bearings:

WSW excellent quality deep groove ball bearing with reasonable price for customers all over the world and can produce various types of bearings,over 200 series and 5000 specifications or so.

Deep groove ball bearings are the most widely used bearing type and are particularly versatile. They have low friction and are optimized for low noise and low vibration which enables high rotational speeds. They accommodate radial and axial loads in both directions, are easy to mount, and require less maintenance than other bearing types.

We promise that WSW only provides excellent quality products with the best price and the most professional service! We sincerely invite all of you to cooperate with us.