WSW Technology Knowledge: Cutting in grinding of peach shaped raceway of four point contact ball bearing

four point contact ball bearings form a peach shape, which is ground into a peach shaped groove at one cut.

Abstract: the peach shaped groove of four point contact ball bearing is formed by adjusting the relative position of the wheel dresser and the wheel on the cut in grinder, and changing the arc eccentricity of the wheel to form a peach shaped groove by one-time cut in grinding.

Key words: peach shaped channel; Grinding wheel dressing; Cut in grinding

At present, the peach shaped groove (whole peach shaped) of four point contact ball bearings can only be processed on the cut in grinder. The outer groove of QJ bearing is ground on 3MB1430A cut in ball bearing outer ring groove grinder, and the inner groove of QJF bearing is ground on 3MZ1310A cut in ball bearing inner ring groove grinder.

1. Formation principle of peach shaped channel

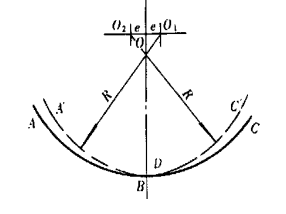

The formation principle of peach shaped channel is shown in Figure 1.

Figure 1

As shown in Figure 1, the arc AB is shifted to the right by the distance of eccentricity e to O1 based on O to form a new arc A'D; Then move the arc BC to the left with O as the base point, and form a new arc DC, intersecting the arc A'D at point D, and the new geometric shape formed by the arc A'D and D'C is the peach shaped groove prime line of the four point contact ball bearing.

When machining the channel on the cut in grinder, the grinding wheel is trimmed into a peach shape for one-time form grinding.

2. Dressing the grinding wheel on 3MB1430A external groove grinder

Fix the positioning block of the grinding wheel dresser in the T-groove on the side of the longitudinal reciprocating workbench of 3MB1430A grinder after proper adjustment. Align the bolt under the positioning block of the dresser with the zero position of the dial gauge on the dial gauge positioning frame on the machine body, and first trim the grinding wheel into an arc shape with a radius of R. After finishing, screw in the bolt under the dresser positioning block to make the dial indicator point towards “+” Stop after turning the eccentricity e in the direction, and trim the grinding wheel for the second time. At this time, only half peach shape appears. After finishing, screw the bolt back in the opposite direction, and the dial indicator pointer returns to “0” Continue to reverse after bit, to “-” Stop when the direction rotation eccentricity e is large or small, trim the grinding wheel for the third time, and the finished grinding wheel will show a complete peach shape, which can be cut in grinding.

3. Dressing the grinding wheel on the 3MZ1310A internal groove grinder

3MZ1310A does not have the positioning gauge frame of 3MB1430A outer groove grinder, so the eccentricity e cannot be measured directly. When dressing the peach shaped grinding wheel, it is necessary to prepare a magnetic meter frame by yourself, fix the magnetic meter frame on the bed, hit the dial gauge tip on the base of the grinding wheel dresser, screw in or screw back the distance of the eccentricity e by the bolt on the base of the grinding wheel dresser, and the dressing grinding wheel needs to be trimmed three times as on the outer groove grinder.

If the position of the wheel dresser on the outer groove grinder remains unchanged, adjust the relative position of the wheel to change the eccentricity of the wheel, while the position of the wheel on the inner groove grinder remains unchanged. If the relative position of the dresser is adjusted to change the eccentricity of the wheel, the wheel can be trimmed into a peach shape. We improved the dresser on the 3me2150 grinder to process ball bearings. When grinding the inner groove of medium and large four point contact ball bearings, we also fixed it on the bed with a magnetic gauge frame, hit the dial gauge tip on the dresser seat to measure the offset of the dresser, and then cut in grinding is carried out after the grinding wheel is trimmed into a peach shape.

More about WSW Angular Contact Ball Bearing:

WSW excellent quality Angular Contact Ball Bearing with reasonable price for customers all over the world and can produce various types of bearings,over 200 series and 5000 specifications or so. Angular contact ball bearing can bear radial load and axial load at the same time. It can work at high speed. The larger the contact angle, the higher the axial bearing capacity. The contact angle is the angle between the connecting line of the contact point between the ball and the raceway in the radial plane and the vertical line of the bearing axis.

https://www.wswbearings.com/products/Deep-Groove-BallBearing/889.html

WBM are professional Angular Contact Ball Bearing manufacturers and suppliers in China, with bulk high-quality products in stock. If you are going to buy a customized taper roller at a competitive price, welcome to get a quotation from the WBM factory. In line with the business philosophy of pursuing excellence, continuous improvement and common prosperity, the ball header, solid steel balls, roller header produced from WBM is absolutely high-quality and inexpensive.